The typical pitch for a helical ribbon is about 0. As the agitator rotates in Ribbon Blender the material is tumbled and carried radically around the.

Pauloabbe Ribbon Blender Capacity Pdf Blender Valve

A second blade available is a 3-spoke ribbon blade with a 25 in.

. Download full-size image Fig. Then the inside developed diamater B square root of PId2 P2. 1 12 in.

A 1-cu-ft batch usually takes just two to three minutes to complete while cycle time for an 18-cu-ft batch would normally be 8 to 10 minutes. Materials Science Performances of Dry solid powder mixing with in a twin Ribbon blade blender have been performed in this work in order to characterize mixing behavior in such a mixer of binary mixtures with different cohesionless materials. Diameter shaft surrounded by a 18 in.

A ribbon blender can also be installed on a stable mezzanine. Calculations for Ribbon Blender You have D outside flight diameter d inside flight diameter P pitch of flight. Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer Its reliable rugged design can be built for capacities over 1000-cuft.

1 14 in. At 100 cu ft a 20- to 25-minute blend time is quite typical. The ribbon blender can also coat solid.

Outer ribbon with a pitch angle of 60. So consider that b is the result of D-d2. Blender selection and design depends on several factors including the.

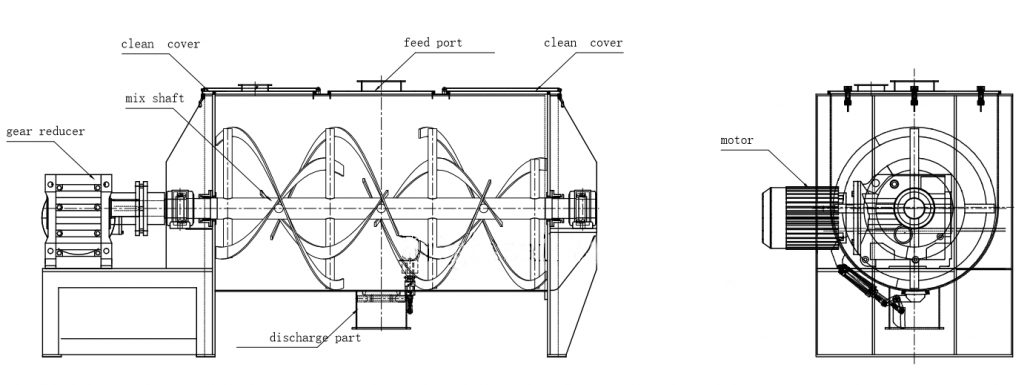

A Best Practices Guide Page 5 of 8 Preparing Solid-Liquid Suspensions. The mixer consists of a rigid fabricated structure motor gear box mixing drum stirrer and tilting device. Some blender selection and specification considerations The desired batch volume determines the size of the blender but product bulk density determines if a standard or heavy-duty model is required.

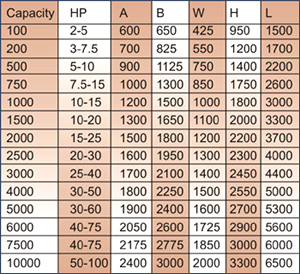

A ribbon blender is normally supplied in a floor-mounted design. Calculations for Ribbon Blender You have D outside flight diameter d inside flight diameter P pitch of flight. Consider the length width height and volume of the vessel as well as the agitator size to customize your ribbon blender to the right size.

Lab scale ribbon blender The Laboratory Mixer is designed for uniformly mixing of dry and wet material and especially suitable for Pharmaceutical Food and chemicals industries. In a ribbon blender a double-helix agitator will move materials towards the center of a trough with the outer blade while the inner blades move the materials towards the outside of the trough. Sep Ribbon Blender Design aritcle details the design construction and operation of Ribbon Blender commonly used for mixing.

The following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair pinion and gear based on their number of teeth and Through examples and sample calculations the concepts of average bulk density total blender capacity Therefore for the purpose of blender design processing in a Ribbon Blender the most reliable drive design is. Unit can be supplied with either double ribbon. Total volume 14 m3 Working volume 07 x Total volume 098 m3 say 1 m3 Bulk density of material to be blended 500 kgm3 Batch weight Working Volume x Bulk Density 500 kg Recommended connected power for 1 m3 blender for 500 kg batch 10 HP.

Recommended connected power for 1 m3 blender for 1000 kg batch 15 HP Case 2. The mixing drum complete with stainless steel body stirrer. The blade speeds utilized are either 20 rpm or 55 rpm.

Now developed the outside diameter A square root of PID2 P2. The effects of fill height and blade rotation speed on mixing homogeneity have been studied. When ingredients are similar in size shape or density mixing is straightforward and fast.

So consider that b is the result of D-d2. Blade widths are typically about 110 of the diameter or about 35 inches for this case. Industry-wide most standard ribbon blenders can typically handle bulk densities of around 35 lbscuft.

This design requires the blender be bolted to a level floor made from a strong suitable material such as heavy-duty concrete that can handle the weight of the equipment and material. Ribbon design which inherently generates pinch points near the vessel walls wherein relatively large and delicate particles may be compressed. The typical pitch for a helical ribbon is about 05 times the diameter or about 18 inches for this blender although that pitch can be adjusted to give an even number or fractional number of turns for the blender length.

Calculations for Ribbon Blender You have D outside flight diameter d inside flight diameter P pitch of flight. Ribbon Blender Double Helical Flighted Shaft. - Value of PI 31415926.

Apr 02 2017 0183 32 Used Sprout Waldron Jacketed Double Ribbon Blender - 145 Cu Ft - Duration 1 07 Ribbon Mixer Blade Design Frigmaires Mumbai India - Duration 0 06 Frigmaires 4085 views. Inner ribbon and a 14 in. Testing is recommended to confirm the appropriate mixer speed cycle time and agitator design for a particular product.

Ribbon blender design calculations Written By colinmathurin25300 Friday April 1 2022 Add Comment Edit Jun 29 2020 An MDL file is a model file used by Warcraft III a real-time strategy game developed by Blizzard Entertainment. Blender and fill level designations. However some basic information and general rules may be sufficient to give direction for this designIn general these.

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Mixer Mixing Machine For Industrial Planning Designs Cad

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

Ribbon Blender Capacity Calculation Ainuok Machinery

Ribbon Blender Capacity Calculation Ainuok Machinery

Ribbon Blender Ribbon Mixer Design Calculation And Selection

0 comments

Post a Comment